100A

100B Literature: Click and Print

| Click To Print DC190330 Silage Bagger | |

| File Size: | 1799 kb |

| File Type: | |

100D Tunnel Replaceable / Removable

You asked for it and we did it! Nortec listens to what the customers / operators have to say. One of the most frequently asked questions is; "How about a removable tunnel?" This makes sense for several reasons. First, at the forefront is shipping of the 9' and 10' Baggers because of the over-width which requires special trucking permits (wide load). The permits are time consuming to obtain. Then the wide load signage and only day time travel is permitted. It's a struggle with our farm customers trying to pick out the correct tunnel for their size operation, also referred to as feed out rate. Their current operation for example may call for a 8' tunnel and as the operation grows and expands so does the feeding requirements. With the new Replaceable Tunnel it's as easy as ordering a larger tunnel. Farm operations have been growing the last few years and buy-outs are common place. If the main farm requires a 10' tunnel and the other operation is smaller and needs an 8' tunnel for that operation, it's an easy and quick switch out.

CUSTOM OPERATORS and RENTAL: These two markets purchase vast amounts of Silage Baggers. Now one Bagger can accommodate 6'-8'-9'-10' bagging needs. 8' and 10' Tunnels are the most popular set up. 6' has its' place in the Silage Bagger custom operator and rental market but would these two industries indeed stock a 6' Bagger? In most cases the answer is no. Would they purchase a low cost 6' tunnel? The answer is yes. Custom Operators and Rental sometime face a plastic bag shortage. In this case the farmers operation has to proceed. If there is a different size plastic bag in inventory that may be the direction the farmer elects to go.

Removal and Installation as easy as 1-2-3. (1) Take pallet forks or lifting device and guide tunnel into bagger bottom location pins. (2) Slide forward. Mating up to top receiver crossover bar. (3) Once installed, flip the flipper levers up to lock in bagger tunnel. Install locking rings on pins. To remove, reverse the procedure.

100E Literature: Click and Print

| Click To Print: 100E Literature Tunnel DC20112 | |

| File Size: | 966 kb |

| File Type: | |

101A Our Bagger

200A Trucking and Transportation

Shipping and transportation costs are greatly reduced because of Nortec's unique removeable tunnel design. Unlike most baggers where the tunnel is NOT removable, it increases shipping cost with additional permits, limited drive time

and rerouting are a few examples.

and rerouting are a few examples.

OR... Click Below for Web Site HD Video Same as You Tube

200B Nortec Financial

300 Features

1... Long Auger

A very heavy-duty auger! Large enough to eliminate "juicing" that occurs during

feeding. This auger does not "chew up" silage while packing, which assures you a

higher quality feed. It is proven by feed salespersons! When running above 175 HP,

use 1,000 RPM PTO. For the best packing results, we recommend 1,700 RPM.

When running at 540 RPM, simply throttle to PTO speed.

A very heavy-duty auger! Large enough to eliminate "juicing" that occurs during

feeding. This auger does not "chew up" silage while packing, which assures you a

higher quality feed. It is proven by feed salespersons! When running above 175 HP,

use 1,000 RPM PTO. For the best packing results, we recommend 1,700 RPM.

When running at 540 RPM, simply throttle to PTO speed.

2... Bag Pan Feature

A hinged bag pan drops down and a bungee rope snaps

loose for easy bag loading.

A hinged bag pan drops down and a bungee rope snaps

loose for easy bag loading.

3...Packer Auger

Our packer auger juts out the back of the bagger and tapers down to allow the feed

to release off the taper for a smooth finish, and a completely full bag.

No back stop is needed!

Our packer auger juts out the back of the bagger and tapers down to allow the feed

to release off the taper for a smooth finish, and a completely full bag.

No back stop is needed!

4..Lights

Standard lighting features include steady tail lights, blinking tail lights,

and turning signal lights.

Optional: Work lights

Standard lighting features include steady tail lights, blinking tail lights,

and turning signal lights.

Optional: Work lights

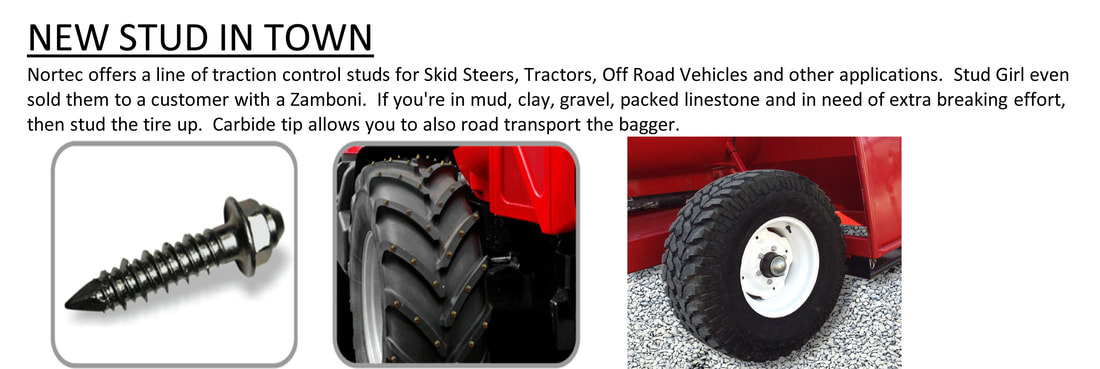

5..Rubber Tires

Rubber tires are rated at 65 MPH. At this speed, the bagger still tows…

just like a trailer.

Special Note: Tires are NEW.. Not used or retreads.

Also note: The deep tread pattern. Aids in extra grip and added breaking power.

Rubber tires are rated at 65 MPH. At this speed, the bagger still tows…

just like a trailer.

Special Note: Tires are NEW.. Not used or retreads.

Also note: The deep tread pattern. Aids in extra grip and added breaking power.

6..Conveyor

Hydraulic

The cylinder slide and tilt the conveyor

for your convenience.

As soon as your wagon or cart is empty, simply pull the hydraulic lever, and bring the

conveyor in.

Reduced crashing into the conveyor!

As soon as your wagon or cart is empty, simply pull the hydraulic lever, and bring the

conveyor in.

Reduced crashing into the conveyor!

7..Drive

System

Our drive system is heavy-duty built, and made for 250-plus horse power.

The Double 80 USA-made chain assures you to pack silage….

Our drive system is heavy-duty built, and made for 250-plus horse power.

The Double 80 USA-made chain assures you to pack silage….

7A Massive 3" Drive Shaft, with USA manufactured Timken Bearing

BEST IN CLASS

BEST IN CLASS

8..Conveyor Features

The extra Wide......... conveyor has tapered side and slat belting for fast,

easy unloading.

Our bagger has handy hydraulic, adjuster flow divider for greater speed.

The extra Wide......... conveyor has tapered side and slat belting for fast,

easy unloading.

Our bagger has handy hydraulic, adjuster flow divider for greater speed.

9..Hydraulic Self- Contained System

The hydraulics are all self-contained for hassel-free operation.

Just place the bag on, engage the PTO, operate the hydraulic levers,

and you are bagging!

The hydraulics are all self-contained for hassel-free operation.

Just place the bag on, engage the PTO, operate the hydraulic levers,

and you are bagging!

10.. Bag and PTO Storage Platform

A large platform is provided for convenient bag and PTO storage.

It offers plenty of space for whatever you need.

Notice the PTO Holder. 540 and 1000 PTO are standard equipment.

Unlike many of our competors which charge you several hundreds of $$

for a PTO option.

A large platform is provided for convenient bag and PTO storage.

It offers plenty of space for whatever you need.

Notice the PTO Holder. 540 and 1000 PTO are standard equipment.

Unlike many of our competors which charge you several hundreds of $$

for a PTO option.

11.. Disc Breaks

The disc brakes are featured with a hand pump for perfect adjustment,

so the wheels do not slide.

You can also use an adjustable rod on your tractor brakes to assist with

bagger brakes.

Also note: The deep tread pattern. Aids in extra grip and added breaking power.

Special Note: Tires are NEW.. Not used or retreads.

The disc brakes are featured with a hand pump for perfect adjustment,

so the wheels do not slide.

You can also use an adjustable rod on your tractor brakes to assist with

bagger brakes.

Also note: The deep tread pattern. Aids in extra grip and added breaking power.

Special Note: Tires are NEW.. Not used or retreads.

400 Picture Gallery

Picture Gallery

500 Axial Flow Bullet Rotor

Bullet Rotor: The rotor is shaped much like a bullet.

Think of it a as a bullet with flighting.

Axial Flow Bullet Rotor

The NORTEC BaggER is equipped up with a very efficient axial flow bullet rotor. By nature, the axial flow rotor will take kinetic energy and converted to pressure.

This system is extremely reliable and efficient.

Very low maintenance is needed.

Efficient and Reliable Axial Flow Bullet Rotor Auger's the silage to the bagger.

Taper rotor design allow's the feed to release off the taper for a smooth finish, and a completely full bag.

The NORTEC BaggER is equipped up with a very efficient axial flow bullet rotor. By nature, the axial flow rotor will take kinetic energy and converted to pressure.

This system is extremely reliable and efficient.

Very low maintenance is needed.

Efficient and Reliable Axial Flow Bullet Rotor Auger's the silage to the bagger.

Taper rotor design allow's the feed to release off the taper for a smooth finish, and a completely full bag.

510A Video Bullet Rotor Operation Right Side View

Notice the heavy flighting........... There are only 2 manufactures in the USA that can bend and form this heavy of flighting.

510B Video Bullet Rotor Operation Left Side View

600 Boom

700A Traction Studs

701B Customer Testimonials

800A You Tube Video

Click Below to Start Video

800B Short Videos

800C Performance Video

800D Video: Talk About: Horse Power Requirements

800E Video: Talk About: Silage Elevator Performance

800D Video: Talk About: Video Conveyor Hydraulic Operation

800E Video: Talk About: Belt Conveyor

800F Video: Talk About: Auger Back Shaft

800G Video: Talk About: High Performance Super Duty Auger

800H Video: Talk About: Disc Brakes

800J Video: Talk About: Disc Brakes Operation and Tire

800K Video: Talk About: Disc Brakes

800L Video: Talk About: Drive System

800M Video: Talk About: Hydraulic Cooling System

800N Video: Talk About: Tool Box

800P Video: Talk About: Plastic / Bag Installation

800Q Video: Talk About: Reasons for NO Cables or Back Stop

800R Video: Talk About: Lights

801A Video: Talk About: Packing Performance

900A DVD Dealer Training Video "Full Length"

1000 You Tube

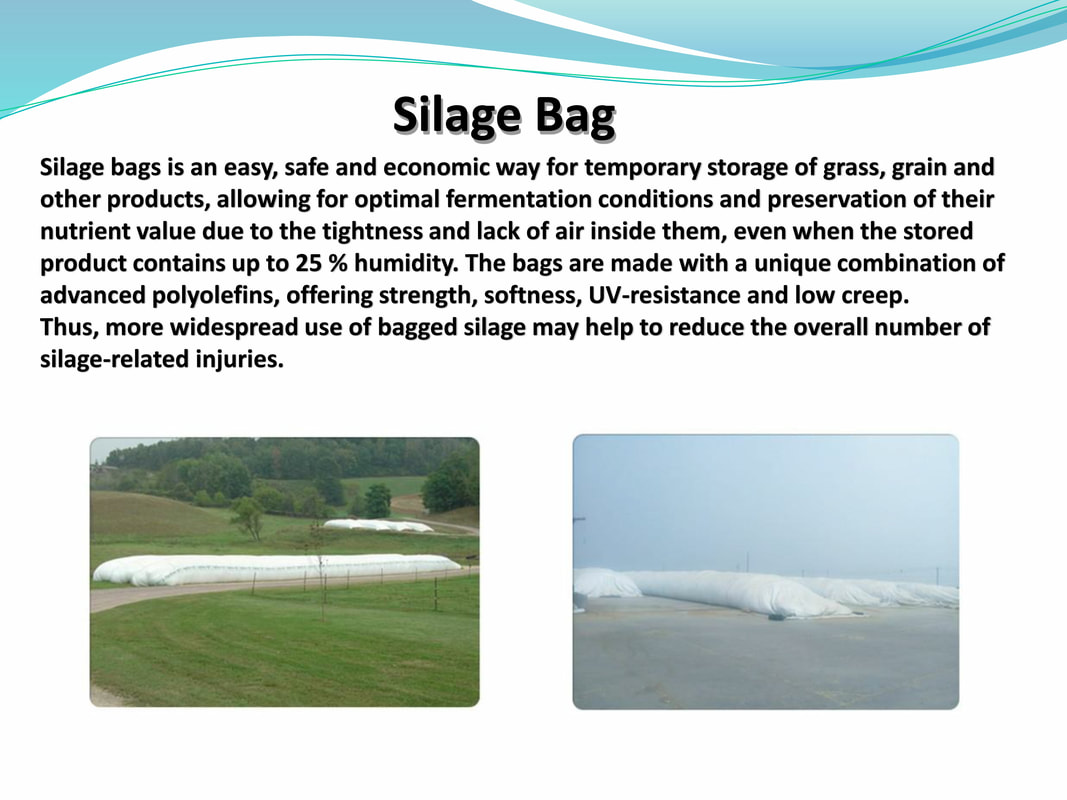

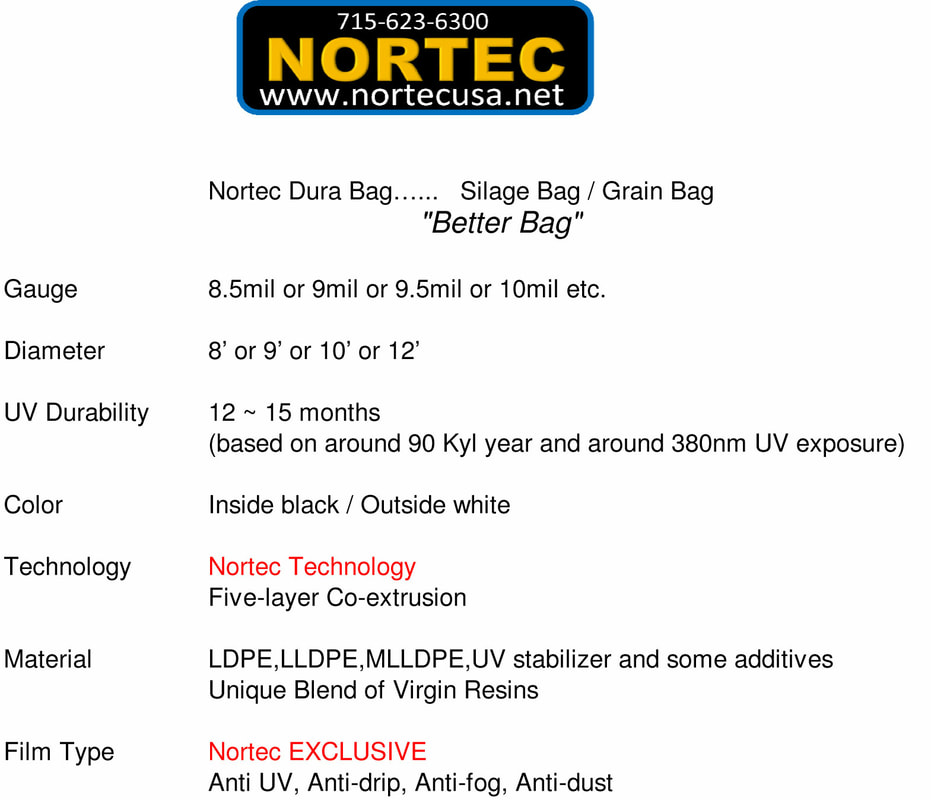

2000 Silage Bag's