Introducing the most advanced soil processor on the market today. Nortec has been producing and manufacturing soil processors for 20 years. This Generation 5 Pro Raptor is destined to become the industry leader. Best news of all it's affordable!

NEW LOWER PRICING $$$$$ - More Features

How did we achieve lower pricing and added value with more features? Simple..... ECONOMICS! The more you build the cheaper the cost pricing is.

Nortec listened to our customers on this 5th Generation Soil Processor. Durability and performance is designed and built into each and every Raptor. The Pro Raptor is manufactured in a state-of-the-art manufacturing facility. Lean manufacturing efficiencies allow for low cost production. This Raptor has features years ahead of the competition. Take for example INDUSTRY EXCLUSIVE side shift frame. Designing, building and manufacturing Soil Processors for 20 years has taught us a thing or two. Take a look at the New Pro Raptor and you will agree, this is the most planned out and well designed soil processor on the market today.

The Professional Grade Series of the Raptor is also known as the PRO Raptor. The PRO Raptor has three series. PRO Raptor Standard, PRO Raptor Heavy Duty and the PRO Raptor Super Duty. Each model is designed for a horse power rating and tractor size. Cost reduction is achieved though this method of engineering. By sharing a common platform it is a very efficient manufactured design.

100A

PRO T6 PRO T7 Standard

T6 25 to 40hp T7 30 to 80hp

6 Foot

Versa Hitch Cat 1 Compliance / Cat 2 Convertible

Manual or Hydraulic Angle

Aggressor "Mining Tooth" Carbide Rotor

Single Chain Case Mounted Slip Clutch

Single Slip Clutch (Chain Case Mounted)

Manual Angle Standard Equipment. Power Angle Optional

T6 25 to 40hp T7 30 to 80hp

6 Foot

Versa Hitch Cat 1 Compliance / Cat 2 Convertible

Manual or Hydraulic Angle

Aggressor "Mining Tooth" Carbide Rotor

Single Chain Case Mounted Slip Clutch

Single Slip Clutch (Chain Case Mounted)

Manual Angle Standard Equipment. Power Angle Optional

100B

PRO HD7 Heavy Duty PRO HD8 Heavy Duty

7 foot and 8 foot

50 to 80hp

Versa Hitch Cat 2 Compliance / Cat 1 Convertible

Manual or Hydraulic Angle

Aggressor "Mining Tooth" Carbide Rotor

Single Slip Clutch (Chain Case Mounted)

Manual Angle Standard Equipment. Power Angle Optional

7 foot and 8 foot

50 to 80hp

Versa Hitch Cat 2 Compliance / Cat 1 Convertible

Manual or Hydraulic Angle

Aggressor "Mining Tooth" Carbide Rotor

Single Slip Clutch (Chain Case Mounted)

Manual Angle Standard Equipment. Power Angle Optional

100C

- Pro Raptor Super Duty

- H.P. Range 80 to 120/150**

- Super 6 6 foot working-processing width

- Super 7 7 foot working-processing width

- Super 8 8 foot working-processing width

- Super 10 10 foot working-processing width

- Super 12 12 foot working-processing width

- Dual slip clutch is standard equipment. One is located on the front input (tractor to gear box). Second one is located on the chain case.

Horse Power Rating on the Pro Raptor Super Duty is 80hp to 150hp.

Also notice side shift "offset" mode.

Versa Hitch is set in Cat 3 setting.

Also notice side shift "offset" mode.

Versa Hitch is set in Cat 3 setting.

- Optional Rear Flex Blade.

Versa Hitch Setting Cat 2.

Sod Buster Option

Coming Soon: Sod Buster Attachment Option. Nortec has several Sod Buster's out in real life operation. Customers are reporting into engineering with outstanding results.

200A Features

| CLICK TO PRINT: raptor_literature_pro_sd_side_2.pdf | |

| File Size: | 507 kb |

| File Type: | |

200B Warranty

200C Powder Coating

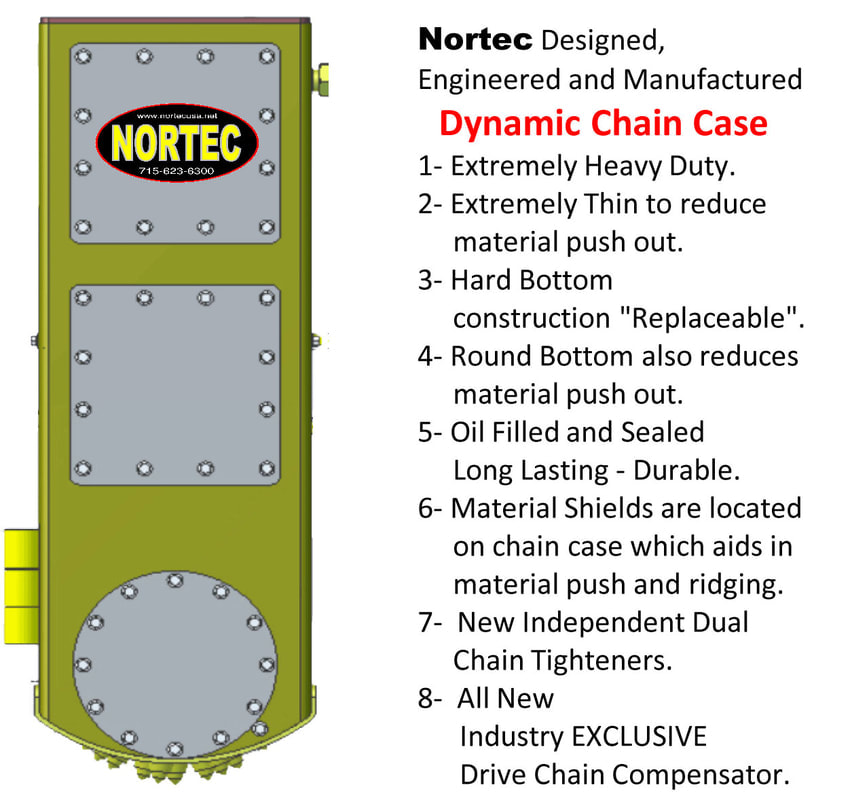

200D Chain Case

Chain Case

- All NEW Nortec chain case. This robust chain case will give you years of

- durability. 20 years of soil processor knowledge went into engineering and

- design of this all new chain case. Slip clutch has been relocated on the chain

- case for faster reaction time. The top jackshaft is a Nortec designed and

- manufactured component.

- All new push (compression) tensioner system.

- This is an up-grade from the old style pull (hook) system.

Oil Filled Chain Case vs Dry Chain Case

Definitely oil filled chain case is far superior then a dry chain case. Several reasons - 1) Longer chain life. 2) Less maintenance. No need to lubricate the chain. It’s self-lubricating. 3) Oil filled chain case keeps the oil in and the CONTAMINANT OUT. 4) In the future if any major repairs such as bearing or sprocket replacement is needed, these items running in oil will make removal easy. Whereas a dry chain case allows dirt and moisture to enter the chain case leading to rust of components, making parts removal difficult. So why would a manufacturer even offer a dry chain case? This is a 2-part answer. First is cost. A dry chain case is a fraction of the cost of an oil filled chain case to manufacture. Second, unless a manufacturer knows what they’re doing and has the engineering knowledge, they will fail on designing an oil filled chain case.

Definitely oil filled chain case is far superior then a dry chain case. Several reasons - 1) Longer chain life. 2) Less maintenance. No need to lubricate the chain. It’s self-lubricating. 3) Oil filled chain case keeps the oil in and the CONTAMINANT OUT. 4) In the future if any major repairs such as bearing or sprocket replacement is needed, these items running in oil will make removal easy. Whereas a dry chain case allows dirt and moisture to enter the chain case leading to rust of components, making parts removal difficult. So why would a manufacturer even offer a dry chain case? This is a 2-part answer. First is cost. A dry chain case is a fraction of the cost of an oil filled chain case to manufacture. Second, unless a manufacturer knows what they’re doing and has the engineering knowledge, they will fail on designing an oil filled chain case.

200E Outboard Slip Clutch

Outboard Mounted Slip Clutch

For years our slip clutch has been in front of the gear box. PTO off tractor to

slip clutch mounted on inputshaft of gear box. Through advanced

engineering discovery, Nortec has found out this is incorrect location.

Once discovered, this was not an easy fix. It involved a major design change and Nortec is pleased to announce outboard chain case mounted slip clutch. This is a vast improvement to the new release Raptor. So why is this location so important? Slip clutch reacts in milliseconds. The further away from the rotor the slip clutch is placed the more reaction time it takes for the slip clutch to react. Under normal conditions the unknown to the operator there is movement inside the slip clutch. The fiber disk is slipping under load. Coming off the rotor is a condition known as back-lashing. The rotor back-lashing is transmitting torque through the chain case to the cross over drive shaft into the gear box and finally to the slip clutch. Over time this will damage the drive system weather it’s the chain or gear box and even affects the bearings.

slip clutch mounted on inputshaft of gear box. Through advanced

engineering discovery, Nortec has found out this is incorrect location.

Once discovered, this was not an easy fix. It involved a major design change and Nortec is pleased to announce outboard chain case mounted slip clutch. This is a vast improvement to the new release Raptor. So why is this location so important? Slip clutch reacts in milliseconds. The further away from the rotor the slip clutch is placed the more reaction time it takes for the slip clutch to react. Under normal conditions the unknown to the operator there is movement inside the slip clutch. The fiber disk is slipping under load. Coming off the rotor is a condition known as back-lashing. The rotor back-lashing is transmitting torque through the chain case to the cross over drive shaft into the gear box and finally to the slip clutch. Over time this will damage the drive system weather it’s the chain or gear box and even affects the bearings.

200F Material End Shields

Material End Shields "Quick Flip"

Kink Bent Side Shields for added strength and durability.

NEW STYLE: Attention to the smallest detail went into engineering the

Raptor Soil Processor. Material end shields may be damaged by hooking

rocks and roots. Nortec solved this problem by first using a new

manufacturing technique called kink bending. This procedure will vastly

increase strength. Second the leading bottom edge of the material side shield

is rounded. This acts as a ski reducing end shield from hooking. The ski

design also aids in jumping which may occur in a straight non rounded design.

Raptor Soil Processor. Material end shields may be damaged by hooking

rocks and roots. Nortec solved this problem by first using a new

manufacturing technique called kink bending. This procedure will vastly

increase strength. Second the leading bottom edge of the material side shield

is rounded. This acts as a ski reducing end shield from hooking. The ski

design also aids in jumping which may occur in a straight non rounded design.

- OLD STYLE: Bent side shields not only costs you down time it’s another

added expense. Here’s some comparisons between the old style and the

new style end shields. Notice the point of damage (bending) has now been

extremely improved and strengthen with a simple kink bend. We also

cleaned up on the holding pin. Much improved pin removal. Thanks to the

new box side frame the lower end shields now is positioned against the

frame. The old style had NO reinforcement structure to butt up against.

NEW STYLE End Shield Location:

The new Pro Raptor relocated the end shield mounts from the inner frame to

the chain case.

Reduces material push out, added strength. Also notice the longer end shield

for added material capacity and more productivity.

The new Pro Raptor relocated the end shield mounts from the inner frame to

the chain case.

Reduces material push out, added strength. Also notice the longer end shield

for added material capacity and more productivity.

- OLD STYLE End Shield Location:

- You can see the vast improvement from the new style compared to the old style. New Style features added durability, less material leakage.

200G

Versa Hitch Combo Cat 1, Cat 2, Cat 3

Versa hitch is a breakthrough in engineering design. 3-point hitch is becoming complicated in today's tractor world. In the past Cat 1 - Cat 2 - Cat 3 were straight forward. Fast forward to today’s world, what your present tractor has for a hitch size and what your future tractor may have. To really complicate the matter. The 50 to 80 hp range, some has Cat 1 others have Cat 2. Don't worry, Nortec Raptor has you covered! The industry exclusive Nortec Versa Hitch covers Cat 1, Cat 2, Cat 3.

Special NOTE: The Versa Hitch will increase the Raptors resale value in the future. Customer is looking for a pre-owned soil processor only to find out it does not have the correct hitch. Not the case with the Raptor Versa Hitch it’s a match.

200H

Compliance Hitch: Quick Hitch COMPATIBLE

Quick Hitches also known as John Deere™ i Match are becoming popular.

This time saving tractor option takes the frustration out of hooking up the

implement to the tractor. Sad fact is most attachment manufacturers are not

complying to this specification. Nortec is pleased to announce all Raptor Soil

Processors are in compliance.

This time saving tractor option takes the frustration out of hooking up the

implement to the tractor. Sad fact is most attachment manufacturers are not

complying to this specification. Nortec is pleased to announce all Raptor Soil

Processors are in compliance.

200J

PTO Drive System

200K

Frame: 4"x4" Structural Steel

Just as your home is built on a foundation, all of the other elements that make up your home, such as the floor structure, walls, staircase, electrical system, and plumbing are either attached to the foundation or use it as a reference point in their design and fabrication. That’s why the Nortec frame must be so precisely engineered and manufactured – to ensure that all of the sub components that must be attached can be assembled to the Raptor with perfect fit and finish, and provide flawless performance for the life of the processor.

200L

Frame: Outboard "Idler Side"

- New Style Side Frame. Cleaner, more attractive look. Looks are only part

- of the story. Increase side frame strength. 4-Bolt bearing assembly with

- 1-1/2" shaft. Compared to the old style notice improvement on side shield

- to frame seal.

Old Style Side Frame: 2-Bolt bearing assembly with 1-3/8" Shaft. Notice

the gap between the end shield and side frame. Reports of material

leakage, leaving windrows.

This major issue has been improved on the Pro Raptor.

the gap between the end shield and side frame. Reports of material

leakage, leaving windrows.

This major issue has been improved on the Pro Raptor.

200M

Torque FLEX Side Frame

Only on Pro Raptor Heavy Duty and Pro Raptor Super Duty. With today’s higher horsepower tractor. Torque Flex

OLD STYLE: As you can see there is a vast difference between the new design

and old design.

Also notice the new design has a 4 bolt flange bearing (protected) the old design

is a 2 bolt pillow block (exposed)

and old design.

Also notice the new design has a 4 bolt flange bearing (protected) the old design

is a 2 bolt pillow block (exposed)

300A

Rotors

20 years of designing and manufacturing Soil Processor Nortec has learned a thing or two. What works and what does not work in designing the ultimate rotor. Nortec offers two styles of rotors. First is the landscaping rotor. Designed for rocks and debris. Second rotor is a processing rotor for excellent grinding.

- All Super Duty Pro Raptors feature an industry exclusive processing rotor. This

- replaceable carbide tooth rotor will offer you years of excellent wear ability.

500 Video

Click on Video Below: Processing Rotor Action

Several key performance features and design in this video.

(1) Notice the excellent grinding action

(2) Thanks too our new Gear Reduction Gear Box. The new Raptor has a much lower rotor speed. Instead of throwing material we are now processing the material. Reason this is so important is the fact the lower rotor speed allows the tooth to achieve its processing / grinding action. Unlike a high speed rotor which will throws the material away from the tooth not allowing it time to process. The low speed rotor will also reduce rock throwing.

(3) Low speed rotor offers a much cooler tooth temperatures which in turn increases tooth life.

(4) 40% more POWER

(5) Notice how smooth the rotor is. 2 Reason for the smooth rotor action. First all rotors are balanced. Second tooth placement. The cork screw tooth placement is a huge advancement in performance.

(6) Notice the reduced material windowing in the angle position. Reason this is so important is. Most rotor designs do not allow grinding action (material break down) which in turn flows out the side leaving windrows. Reason for the reduced windowing on the Raptor is for the fact much of the material is processed and flows threw the rotor. This new design break though allows for a much more efficient material grinding action.

(1) Notice the excellent grinding action

(2) Thanks too our new Gear Reduction Gear Box. The new Raptor has a much lower rotor speed. Instead of throwing material we are now processing the material. Reason this is so important is the fact the lower rotor speed allows the tooth to achieve its processing / grinding action. Unlike a high speed rotor which will throws the material away from the tooth not allowing it time to process. The low speed rotor will also reduce rock throwing.

(3) Low speed rotor offers a much cooler tooth temperatures which in turn increases tooth life.

(4) 40% more POWER

(5) Notice how smooth the rotor is. 2 Reason for the smooth rotor action. First all rotors are balanced. Second tooth placement. The cork screw tooth placement is a huge advancement in performance.

(6) Notice the reduced material windowing in the angle position. Reason this is so important is. Most rotor designs do not allow grinding action (material break down) which in turn flows out the side leaving windrows. Reason for the reduced windowing on the Raptor is for the fact much of the material is processed and flows threw the rotor. This new design break though allows for a much more efficient material grinding action.

Short Video: Click Below To Watch

Fine Tooth Processing Rotor

Fine Tooth Processing Rotor

Notice the smooth processing action. Thanks to the NEW tooth placement this provides smooth, aggressive soil processing action. Take notice in this hard pack "Sod" condition there is little to NO jumping. Also notice how fine the material is being processed. This new Raptor is extremely POWERFUL due to the new Power Gearing.

Also take note on the NEW rear processing blade. Once the processed material flows though and over the rotor, material enters into the second stage of processing. The blade will now grade and level the processed material leaving a smooth surface.

Also take note on the NEW rear processing blade. Once the processed material flows though and over the rotor, material enters into the second stage of processing. The blade will now grade and level the processed material leaving a smooth surface.

- Short Video: Click Below To Watch.

- Variable-Adjustable "Side Shift" Standard Equipment

Click Below to View You Tube Video